Rubber Compounds

Zenith Rubber produces customer specific rubber compounds that can be transformed to suit different industrial applications, having a capacity to manufacture 100 metric tons of rubber compounds per day.

Zenith's compounds are of the highest quality ensuring that they comply with local and international standards and provides an extensive portfolio of types and grades. The technical know-how of our specialists and high material competence are core elements of our product portfolio.

The compound preparation is done in state of the art modern mixers and in subsequent compound finishing lines offering a high degree of automation.

The compounds are formulated based on our clients’ requirements for various techniques such as, calendaring, moulding by compression and injection, extrusion of profiles, coatings for textiles etc.

The compounds can be formulated to have a shelf life of up to 180 days (with or without curatives) With over 50 years of experience we fulfil the needs of various sectors like automotive, oil and gas, pharmaceutical, mass transit/railways, OEM’s etc.

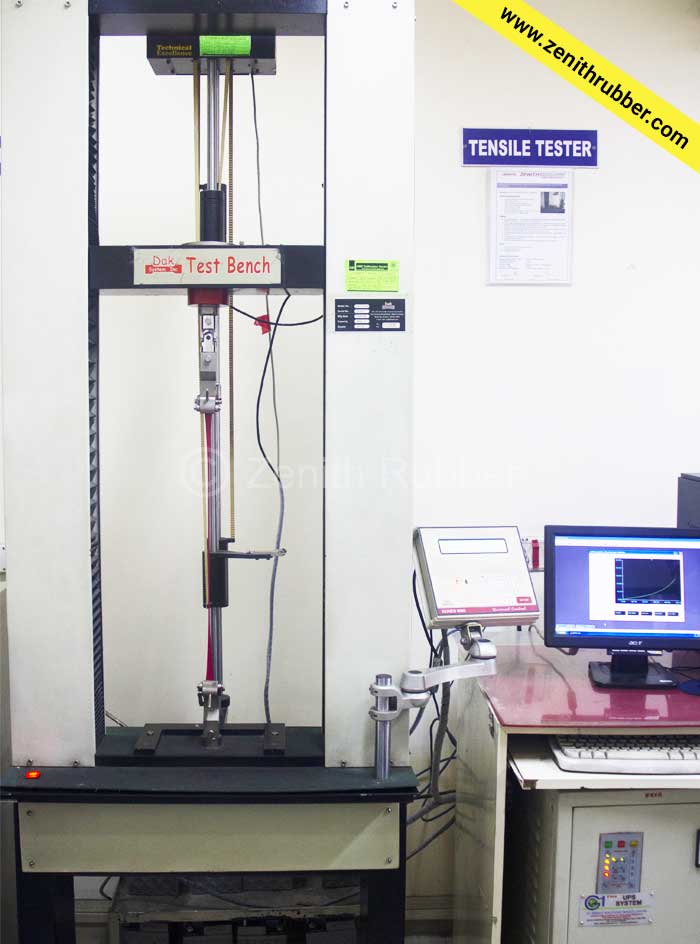

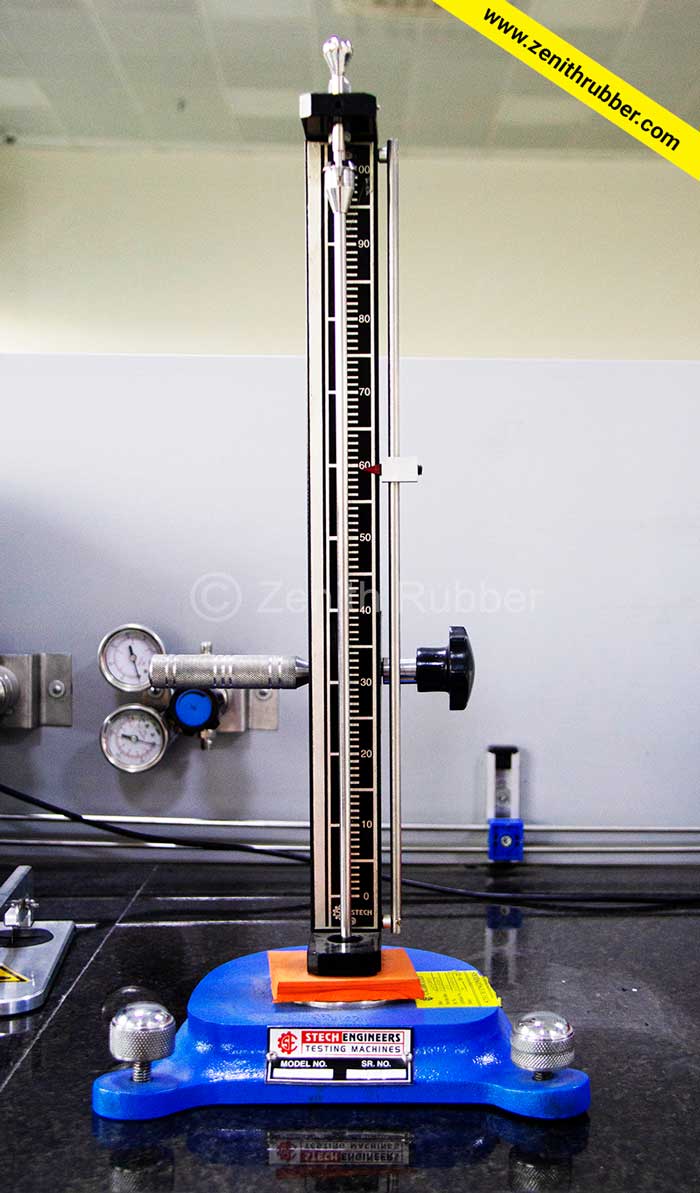

Range Of Zenith Testing Equipment

Our testing facilities have been Certified under ISO 17025

Raw Material Testing Equipment

Finished Product Testing Equipment

Product Range

- Natural Rubber

- Styrene Butadiene Rubber (SBR)

- EPDM

- Polybutadiene Butadiene Rubber (PBR)

- Chloroprene Rubber

- Nitrile Rubber

- Chlorosulfonated Polyethylene (CSM)

- Butyl Rubber (IIR)

- Silicone

- Fluoroelastomer (FKM)

- CPE

Compounds’ Technical Application

- Compression/Injection Moulding: O- Rings, Gaskets, Oil seals, Sealing, Diaphragms, membranes.

- Coatings for Rollers, Vessels and Tanks

- Calendered Sheets

- Conveyor, Belts and Pulleys

- Extruded/Vulcanised: Hoses, Tubes, Profiles, Strips, Cords.

- Anti-Vibration Mounts and Sleeves.

Industrial used in

- Automotive

- Oil & Gas

- Railways

- Defence

- Ships

- Pharmaceutical

- Chemical

- Agriculture

- Household Appliances

- Power supply