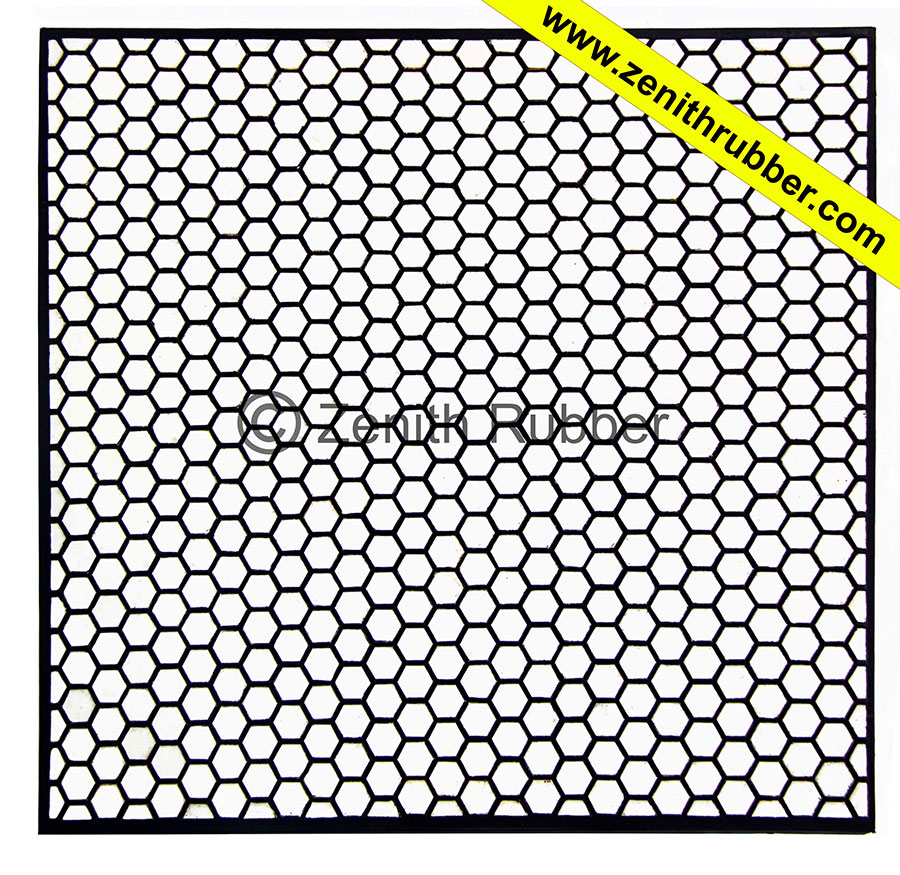

Zen-Star Ceramic Wear Pad

Zen-Star CP Ceramic wear pads are vital components in the mining industry, serving as robust solutions to combat abrasive wear and impact on critical equipment. These wear-resistant pads are crafted from high-quality ceramic materials known for their exceptional hardness and durability. They are specifically designed to protect surfaces, such as conveyor systems, chutes, and hoppers, from the erosive forces of abrasive materials like ores, coal, and minerals commonly encountered in mining operations.

Properties

Ceramic wear pads exhibit remarkable properties, including high hardness, wear resistance, and impact resistance, ensuring prolonged equipment life under harsh mining conditions. They can effectively withstand the abrasive effects of materials while providing excellent resistance to chemical corrosion, making them ideal for diverse industrial settings.

Applications

In mining, ceramic wear pads find extensive use in conveyor systems, chutes, feeders, and other equipment involved in material handling processes. By safeguarding these critical components, ceramic wear pads contribute significantly to minimizing downtime, reducing maintenance costs, and optimizing mining operations overall.

Applications

- CERA-WEAR Zen-Star Ceramic Wear Pads have been designed primarily for use as a ceramic lining for the wear and corrosion protection of steel surfaces.

- It’s mainly used for high-speed wet abrasion applications such as slurry handling in the mineral processing industry but can be used for any fine particle abrasion applications.

Note

- Custom width and length is available on request

- Custom colours available on request